What is Uncoated Paper? And Other Frequently Asked Questions

You’ve probably heard us say that Accent® Opaque is a premium uncoated sheet. But what does that mean? We get a lot of questions on the topic of paper coating, particularly when it comes to how uncoated paper behaves on press. Questions like:

- What is the difference between coated paper and uncoated paper?

- Should I use coated paper or uncoated paper for my project?

- What is paper coating anyway?

Well, we’re here to answer these questions and more. Let’s get into it!

Q: What do people mean when they say a paper is uncoated?

A: In order to define uncoated paper, we really need to start with coated paper. Papers can be coated with all sorts of things, including clay, talc, polymers, pigments and more. Often, the coating is a mixture of one or more of these materials held together with a binder like starch.

Generally, paper coatings are used to create a specific look, feel or print performance. Different coatings have different effects; some give the paper a smoother feel by filling in the miniscule valleys in the paper's surface. Others create a glossy texture, and still others provide water resistance or UV protection. In all cases, the coating helps to keep the ink on the surface of the paper, which means crisp text and images.

Uncoated paper, on the other hand, has no coating to prevent ink absorption. How sharp a printed image is will depend on the smoothness and brightness of the paper. The smoother the paper, the better the ink holdout!

Q: What is the texture of uncoated paper?

A: Since uncoated paper doesn’t use a coating to create an extra-smooth surface, the texture of a particular sheet depends on how it’s made and how highly calendered it is. Calendering paper involves passing it through steel rolls that exert enough pressure to compress the fibers. A high level of calendering makes the paper surface extremely level and uniform, as with Accent Opaque Super Smooth.

Q: How can I tell if a paper is coated?

A: If your stock is glossy, it’s probably coated. But while some coated papers have an obvious gloss or sheen, matte coated papers can look more like an uncoated sheet. Likewise, smoothness is not necessarily an indicator of coating, as some uncoated papers are incredibly smooth. If you’re unsure, the best way to know for certain is to look at the specs from your paper manufacturer.

Q: Should I choose a coated paper or an uncoated paper for my project?

A: We believe that there is a perfect paper for every project. Here are some rules of thumb to keep in mind — though there are certainly exceptions to every rule.

- Coated papers are great for creating super-sharp images, since the coating prevents the paper from absorbing any ink at all.

- If your project includes a lot of text, avoid glossy coated papers, as the gloss can create a glare that makes it hard to read.

- When it comes to color, the word most often associated with coated papers is “vibrant” while the word most often associated with uncoated papers is “rich.”

- Both types of paper stand up well to special finishes like foil stamping and die cutting, though uncoated papers are typically the best choice for embossing.

- Some coated papers are difficult to write on with a pen or marker.

- If you’re printing in a hurry, uncoated paper generally dries faster because it absorbs the ink.

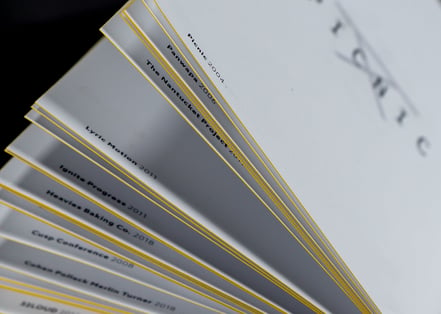

Q: Can you show me an example of a project that was printed on uncoated paper?

A: So many! We love providing project inspiration. Check out our extensive gallery of projects printed on Accent Opaque.

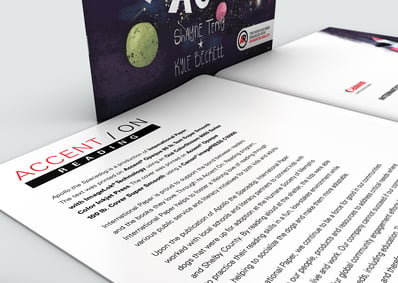

Q: So what makes Accent a premium uncoated paper?

A: Accent Opaque — available in Smooth, Super Smooth and Vellum — is highly calendered for excellent ink holdout and is 97 brightness, both features that make for excellent print performance in high-end and graphic arts applications.

Q: What about Accent Opaque Digital Treated? I read that it’s uncoated but how does that perform on inkjet presses?

A: Inkjet presses do not require a special sheet, but the dye-based and pigment inks used in these printing processes have an incredibly high water content. Our digital treated sheets, which are available for both inkjet and Indigo presses, are unique in that the treatment is in the sheet, not on the sheet. This treatment helps to keep each ink dot from spreading, which results in greater clarity, but it’s not actually a coating, so there’s no additional gloss or sheen on the sheet.

Have a question we didn’t cover here? Send us a note or connect with us on social media and we’ll address it in our next newsletter.